manager

NL 159/16 | Amendments (03-15) to the International Maritime Solid Bulk Cargoes (IMSBC) Code

Oct 06, 2016

Refers to: Ship Managers / Owners, PHRS Surveyors / Representatives

Action Date: January 1st 2017

Amendments (03-15) to the International Maritime Solid Bulk Cargoes (IMSBC) Code will enter into force on 1 January, 2017, and may be implemented voluntarily since 1 January, 2016.

The amendments include the following individual schedules with specific carriage requirements for the following Group B cargoes (cargoes which possess a chemical hazard which could give rise to a dangerous situation on a ship):

- Amorphous Sodium Silicate Lumps

- Boric Acid

- Wood Pellets Containing Additives and/or Binders

- Wood Pellets not Containing any Additives and/or Binders. (The existing individual schedule for Wood Pellets was deleted)

Other changes to the IMSBC Code include the following:

- A new test procedure is to be used for determining the Transportable Moisture Limit (TML) of iron ore fines, a Group A cargo which is now included in the Code as it may liquefy if shipped at a moisture content in excess of its TML, and which has been associated with the loss of several vessels in the past years.

- Shippers will be responsible for declaring whether a solid bulk cargo is:

- HME (Harmful to the Marine Environment), in which case the relevant discharge restrictions should apply, or

- Non-HME, based on the criteria contained in new Section 14 ‘Prevention of pollution by cargo residues from ships’. (this provision is recommendatory)

- A fire safety risk assessment is required to be conducted by crew on ships with conveyor systems for self-unloading.

- For MHB (Materials Hazardous only in Bulk) cargoes, a notational reference will explain the specific chemical hazard(s) of the cargo and will be listed in the “Class” cell of the characteristics table for each individual schedule.

Certification against the IMSBC Code is voluntary. Ship-owners and operators can request from PHRS to include the new cargoes into their ship' IMSBC certificate after the application dates.

For more details on the amendments and a full list of the new cargoes added to the IMSBC Code, please see refer to the Resolution MSC.393(95).

NL 158/16 | Caribbean MOU Concentrated Inspection Campaign (CIC) on Crew Familiarisation with Enclosed Space Entry

Sep 02, 2016Refers to: Ship Managers / Owners, PHRS Surveyors / Representatives

Vessel Type: All Vessels

Action Date: 1 Sept. 2016 - 30 Nov. 2016

The Caribbean MOU on Port State Control (CMOU) has announced a concentrated inspection campaign (CIC) on crew familiarisation for enclosed space entry. The CIC will run from 1 September 2016 to 30 November 2016.

The aims of the campaign are to ensure compliance with the applicable requirements of the SOLAS, STCW, MLC and ILO Conventions; ensure that masters, officers and crew members are familiar with relevant equipment and have received training in carrying out their duties; raise safety awareness among crew serving on board; and ensure that ships have effective procedures and measures in place to safeguard seafarers when entering and working in enclosed spaces on board ship.

During port state inspections, officers will check in detail the procedures and measures that are in place for enclosed space entry. Port state control officers will use a questionnaire to establish that crew members are familiar with the relevant equipment and have received training to identify and understand the hazards associated with enclosed space entry. A copy of the questionnaire is not publicly available but CMOU advise they “will not depart from standard inspections practices when it comes to SOLAS regulations with respect to enclosed space entry.”

If a deficiency is found, actions by the port state may vary from recording a deficiency and instructing the master to rectify it within a certain period to detention of the ship until the deficiency has been rectified. Any detention will be published in the monthly detention lists of the Caribbean MOU.

The results of the campaign will be analysed and the findings will be presented to the governing body of the CMOU for submission to the IMO.

PHRS’s team remains at your disposal for any information/clarification you may need on the above.

Refers to: Managers / Owners, PHRS Surveyors / Representatives

Vessel Type: All Vessels

Action Date: January 18th, 2017

The 2014 amendments to the Maritime Labour Convention, 2006 will come into force on 18 January 2017.

The changes relate to financial security and are as follows.

Standard A2.5.2 – Financial Security

This standard requires a financial security system to be provided to assist seafarers in the event of abandonment. The standard defines abandonment as:

- when the shipowner fails to cover the cost of the seafarer’s repatriation; or

- when the shipowner has left the seafarer without the necessary maintenance and support; and

- when the shipowner has otherwise unilaterally severed their ties with the seafarer, including failure to pay contractual wages for a period of at least two months.

Ships will have to carry on board a certificate or other documentary evidence of financial security issued by the financial security provider. New Appendix A2-1 will detail the information required to be on the certificate or documentary evidence.

Standard A4.2.1 – Shipowner’s Liability

This standard sets out minimum requirements for a system of financial security that assures compensation in the event of a contractual claim (see the definition under Standard A4.2.2 below). Again, ships will be required to carry a certificate or other documentary evidence of financial security issued by the financial security provider.

Standard A4.2.2 – Treatment of Contractual Claims

This standard defines ‘contractual claim’ as “any claim which relates to death or long-term disability of seafarers due to an occupational injury, illness or hazard as set out in national law, the seafarers’ employment agreement or collective agreement.”

The standard also requires that effective means are in place to deal with and settle contractual claims for compensation.

Appendices A4-1 and B4-1

Appendix A4-1 details the evidence of financial security that is required. Appendix B4-1 details a model Receipt and Release Form, referred to in new Guideline B.4.2.2.

Where there is more than one financial security provider for repatriation or shipowner’s liability, documentary evidence from each provider shall be carried on board.

What the changes mean for the Declaration of Maritime Labour Compliance (DMLC)

Financial security for repatriation and financial security for shipowner’s liability are both areas that have to be inspected and approved when a ship is certified in accordance with Standard A5.1.3, paragraph 1. The DMLC Part I will need to be re-issued by the flag administration and the DMLC Part II will have to be updated by the shipowner.

Flag administrations have yet to confirm the form of financial security that will be acceptable but it is likely that most administrations will accept the proposal by the International Group of P & I Clubs.

Do not hesitate to contact us for any information/clarification you may need on the above.

Refers to: Managers / Owners, PHRS Surveyors / Representatives

Vessel Type: Panamanian Flagged Vessels

Action Date: August 2016

According to amended MMC-131 published from Panama Maritime Authority (PMA), starting from August 2016, the Panamanian Administration does not authorize the issuance of a Short Term International Ship Security Certificate (ISSC) after carried out the Initial Verification, except only after the Renewal ISSC Verification and in some cases described in point 9 of the said Circular.

Recognized Security Organizations (RSOs) will be able to issue a Short Term ISSC, with validity not exceeding a five (5) month period, ONLY in the following cases, according to point 9 of the Circular:

- After the successful completion of the Renewal ISSC Verification

- Change of vessel name

- Change of physical address of the operator company

- Change of name of the operator company

- Change of tonnage

- Change of type of vessel

- Change of Company IMO Number

All RSOs must coordinate with the operator/owner to complete all the inspections/audit or visits during the validity of the ISSC interim (validity no more than six months) taking into consideration that the company operator needs to apply for the ISSC Full Term to any Segumar technical Office.

Also, PMA requests from all RSOs and company operators to avoid requesting an ISSC certificate extension. The issuance of a second interim will not be allowed.

By virtue of the above-mentioned amendment to the procedure of the issue of the Full Term ISSC certificate by PMA, all PHRS surveyors, auditors, representatives and clients (owners/managers) are hereby informed as follows:

- The relative procedure for the issue of a Full Term ISSC certificate on Panamanian flagged vessels shall be fully enforced by PHRS with immediate effect. PHRS, as Panamanian Recognized Security Organization (RSO) collaborated from the vessels’ company operators should ensure to make all the necessary arrangements to complete the Initial verification in order to apply for the ISSC Full Term on time.

- Owners/Managers and PHRS Auditors are requested to submit all the pertinent documentation required from an Interim ISSC Audit according to the relative PHRS procedure (audit reports, SSP for review/approval, etc) as soon as possible but not later than 2 months from the issue of the Interim ISSC certificate (validity no more than six months).

- The Initial ISSC Verification should be carried out at least 1 month before the expiry of the Interim ISSC certificate in order to enable the smooth submission of the required documentation (according to MMC-205) to a Segumar technical Office, for the issue of a Full Term ISSC certificate, before the expiry of the Interim ISSC Certificate.

The relative PHRS procedural requirements (PHRS Instructions for ISPS Code certification) will be updated accordingly and will be distributed to all interested parties for their perusal.

Refers to: All Vessels

Action Date: 1st Sept. - 30th Nov. 2016

PHRS would like to inform that, according to the Press Release of July 28th 2016, Paris Memoranda of Understanding (MoU) on Port State Control will launch a Concentrated Inspection Campaign (CIC) on the Maritime Labour Convention, 2006 (MLC,2006).

The aim of the CIC is to verify that the minimum standards for working and living conditions have been implemented on board. This inspection campaign will be held for a period of three months, commencing from 1 September 2016 and ending 30 November 2016.

The ship’s procedures and measures that are in place with respect to MLC,2006 will be checked in detail for compliance with the requirements during a regular Port State Control inspection.

Port State Control Officers (PSCOs) will use a list of 12 selected questions to ensure that the required certificates and documentation are present, in particular those related to the seafarers on board. Additionally there are questions aimed at verification of records of the inspections of the accommodation, food and catering, and whether a safety committee has been established.

When deficiencies are found, actions by the port State may vary from recording a deficiency and instructing the master to rectify it within a certain period of time to detaining the ship until serious deficiencies have been rectified. In the case of detention, publication in the monthly detention lists of the Paris MoU web sites will take place.

In the frames of the better performance of the ships against this CIC, PHRS will take the initiative to ensure compliance of all applicable ships with the relative requirements of the MLC 2006 Convention.

Therefore, all inspections which will be carried out onboard ships certified by PHRS in the period between 1 August 2016 and 30 November 2016 will require from the attending PHRS Surveyor the mandatory conduct of the CIC and the results will be brought to the attention of the ship Master, Owner/Manager for taking the appropriate remedial actions in case deficiencies may be found.

Click here to download the PHRS’ CIC Checklist.

For your further information please refer to the official Paris MOU’s Press Release and CIC Questionnaire.

Remaining at your disposal for any further clarification and/or assistance you may need.

Refers to: All SOLAS – certified vessels

Action Date: July 1st 2016

New regulation aimed at protecting seafarers who need to enter enclosed spaces, by requiring ships to carry portable atmosphere testing equipment on board, enters into force on 1 July 2016.

Seafarers may be called upon to enter enclosed spaces on ships to manage or obtain equipment, assist a colleague or to inspect vital engine parts.

Enclosed spaces are spaces that have limited openings for entry and exit, inadequate ventilation and are not designed for continuous worker occupancy. The atmosphere in any enclosed space may be oxygen-deficient or oxygen-enriched and/or contain flammable and/or toxic gases or vapours, thus presenting a risk to life.

The new regulation XI-1/7 Atmosphere testing instrument for enclosed spaces in the International Convention for the Safety of Life at Sea (SOLAS), requires ships to carry an appropriate portable atmosphere testing instrument or instruments, capable, as a minimum, of measuring concentrations of oxygen, flammable gases or vapours, hydrogen sulphide and carbon monoxide, prior to entry into enclosed spaces.

Enclosed spaces covered by the regulation include, but are not limited to, cargo spaces, double bottoms, fuel tanks, ballast tanks, cargo pump-rooms, cofferdams, chain lockers, void spaces, duct keels, inter-barrier spaces, boilers, engine crankcases, engine scavenge air receivers, sewage tanks, and adjacent connected spaces. The list is not exhaustive and enclosed spaces should be identified and listed on a ship-by-ship basis.

Similar requirements for offshore drilling units enter into force, under amendments to the Code for the Construction and Equipment of Mobile Offshore Drilling Units (1979, 1989 and 2009 MODU Codes).

Associated Guidelines to facilitate the selection of portable atmosphere testing instruments for enclosed spaces as required by SOLAS regulation XI-1/7 (MSC.1/Circ.1477) have been agreed, to facilitate the selection of a portable atmosphere testing instrument for enclosed spaces.

Refers to: Ship Owners / Operators, PH.R.S. Representatives

Action Date: July 1st 2016

What are the new rules?

On 1 July 2016, new requirements to verify the gross mass of a packed container enter into force under the International Convention for the Safety of Life at Sea (SOLAS).

Why have the requirements for verification of the gross mass of the container been introduced?

Knowing the accurate gross mass of a packed container is critical to ensure correct stowage and stacking and avoid collapse of container stacks or loss overboard.

This is an important safety measure, which is aimed at saving lives and preventing injury and the destruction of property.

Is declaration of gross mass a new requirement?

There has always been a requirement in SOLAS to declare the gross mass of cargo and containers. The new requirement adds an extra level requiring verification of the mass.

This is to ensure that the mass declared is a true reflection of the gross mass of the packed container, in order to avoid injury, cargo damage, loss of containers, and so on.

How can the gross mass be verified?

- Method 1: Weighing the packed container using calibrated and certified equipment; or

- Method 2: Weighing all packages and cargo items, including the mass of pallets, dunnage and other securing material to be packed in the container and adding the tare mass of the container to the sum of the single masses, using a certified method approved by the competent authority of the State in which packing of the container was completed.

Method 2 will not be practical for shippers of bulk commodities like iron ore, grain, etc.,

Who provides the verified gross mass?

The shipper is responsible for providing the verified gross mass by stating it in the shipping document and submitting it to the master or his representative and to the terminal representative sufficiently in advance for use in the preparation of the ship stowage plan.

Who is the shipper?

The shipper is defined as a legal entity or person named on the bill of lading or sea waybill or equivalent multimodal transport document (e.g. "through" bill of lading) as shipper and/or who (or in whose name or on whose behalf) a contract of carriage has been concluded with a shipping company. The shipper may be a manufacturer, ship agent, freight forwarder, etc.

What will happen if the verified gross mass is not provided?

The verified gross mass is a condition for loading a packed container onto a ship. A packed container, for which the verified gross mass has not been obtained sufficiently in advance to be used in the ship stowage plan, will be denied loading onto a ship to which the SOLAS regulations apply

Who decides on the “certified method” of weighing?

This is the responsibility of the competent authority of the State in which packing of the container was completed.

Who will enforce the regulations?

Like other SOLAS provisions, the enforcement of the SOLAS requirements regarding the verified gross mass of packed containers falls within the competence and is the responsibility of the SOLAS Contracting Governments. Contracting Governments acting as port States should verify compliance with these SOLAS requirements. Any incidence of non-compliance with the SOLAS requirements is enforceable according to national legislation.

Who pays if the gross mass of a container is not verified?

A packed container, for which the verified gross mass has not been obtained sufficiently in advance to be used in the ship stowage plan, will be denied loading onto a ship to which the SOLAS regulations apply. Any costs associated with the non-loading, storage, demurrage or eventual return of the container to the tendering shipper of the container should be subject to contractual arrangements between the commercial parties.

What if a container arrives for onward transportation without a verified gross mass?

While the shipper is responsible for obtaining and documenting the verified gross mass of a packed container, section 13 of the Guidelines regarding the verified gross mass of a container carrying cargo (MSC.1/Circ.1475) contains contingencies for containers received without a verified gross mass.

In order to allow the continued efficient onward movement of such containers, the master or his representative and the terminal representative may obtain the verified gross mass of the packed container on behalf of the shipper. This may be done by weighing the packed container in the terminal or elsewhere, but whether and how to do this should be agreed between the commercial parties, including the apportionment of the costs involved.

What will happen with regards to containers loaded prior to 1 July 2016 for transhipment?

The Maritime Safety Committee (MSC) at its 96th session in May 2016 agreed that while there should be no delay in the implementation of the SOLAS requirements, it would be beneficial if Administrations and port State control authorities could take a “practical and pragmatic approach” when enforcing them, for a period of three months immediately following 1 July 2016. This would help ensure that containers that are loaded before 1 July 2016, but transhipped on or after 1 July 2016, reach their final port of discharge without a verified gross mass and it would provide flexibility, for three months immediately after 1 July 2016, to all the stakeholders in containerized transport to refine, if necessary, procedures (e.g. updated software) for documenting, communicating and sharing electronic verified gross mass data.

The MSC agreed MSC.1/Circ.1548 Advice to Administrations, port State control authorities, companies, port terminals and masters regarding the SOLAS requirements for verified gross mass of packed containers.

What are the potential problems arising from misdeclared gross mass of a container?

There are a number of potential problems which could arise from a misdeclared container. They include:

- incorrect vessel stowage decisions;

- re-stowage of containers (and resulting delays and costs), if the overweight condition is ascertained;

- collapsed container stacks;

- containers lost overboard (both those overweight and containers that were not overweight);

- cargo liability claims;

- chassis damage;

- damage to ships;

- stability and stress risks for ships;

- risk of personal injury or death to seafarers and shore-side workers;

- impairment of service schedule integrity;

- supply chain service delays for shippers of properly declared containers;

- lost revenue and earnings;

- last minute shut-outs of confirmed, booked and available loads when the actual mass on board exceeds what is declared and the total cargo mass exceeds the vessel limit or port draft limit;

- impairment of ship’s optimal trim and draft, thus causing impaired vessel efficiency, suboptimal fuel usage, and increased emissions from ships;

- liability for accidents and fines for overweight containers on roads, and resulting time and administrative efforts and costs to seek reimbursement from responsible parties; and

- loss of revenue for customs authorities in cases where duties or tariffs are applied by weight measurement of a commodity.

What other work has IMO done to prevent loss of containers or problems with containers?

The new requirement to verify the gross mass of a packed container is just one element of the work that IMO has been doing to address losses of containers.

IMO has worked with the International Labour Organization (ILO) and the United Nations Economic Commission for Europe (UNECE), to develop a non-mandatory global code of practice for the handling and packing of cargo transport units for transportation by sea and land. The 2014 IMO/ILO/UNECE Code of Practice for Packing of Cargo Transport Units (CTU Code), along with related informative material, can be downloaded here.

At the request of IMO, the International Organization for Standardization (ISO) is revising relevant ISO standards (ISO 1161:Series 1 freight containers – Corner fittings – Specifications; and ISO 3874: Series 1 freight containers – Handling and securing) in order to incorporate the most recent advances in container handling and securing equipment, taking account of the latest generation of container ships with design capacity in excess of 18,000 TEU and including design and strength characteristics for automatic twistlocks.

IMO has also adopted the Code of Safe Practice for Cargo Stowage and Securing (CSS Code).

Where can I find out more?

Contact your national maritime Administration for specific advice and guidance: contact points.

Please visit the IMO webpage: Verification of the gross mass of a packed container

Download the text of the SOLAS regulations.

Download the IMO Guidelines regarding the verified gross mass of a container carrying cargo.

Download MSC.1/Circ.1548 Advice to Administrations, port State control authorities, companies, port terminals and masters regarding the SOLAS requirements for verified gross mass of packed containers.

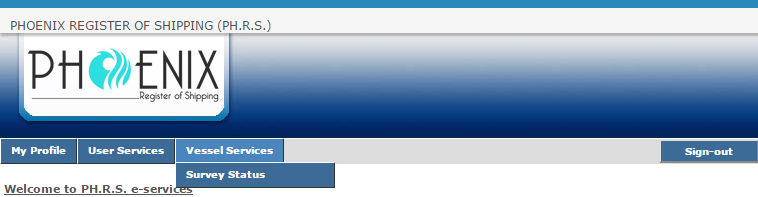

NL 152/16 | Ships’ Survey Status Online

Jun 28, 2016

Ships’ Survey Status Online

Refers to: Ship Owners / Operators, PH.R.S. Representatives

Action Date: 28 June 2016

Phoenix Register of Shipping from now on enables all registered users in the e-services area to have access in public information concerning Survey Status of vessels online.

In case you do not have an e-services account you may visit our website ( www.phrs.gr ) and register online in order to gain access to the latest PH.R.S. e-Library content.

Do not hesitate to contact us for any difficulty you might face using this service at mail@phrs.gr.

We remain at your disposal,

PH.R.S. – Head Office

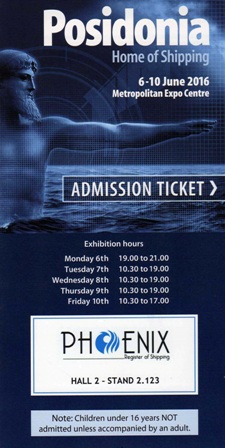

Posidonia | 2016

May 31, 2016Phoenix Register of Shipping is proud to announce its participation to the most famous International Shipping Exhibition: Posidonia - 2016.

You are kindly invited to visit us from 6 June to 10 June at our Stand: No. 2.123 (Hall 2) at Metropolitan EXPO in Athens – Greece.

We hope have the pleasure to meet you all there.

PHRS – Head Office.

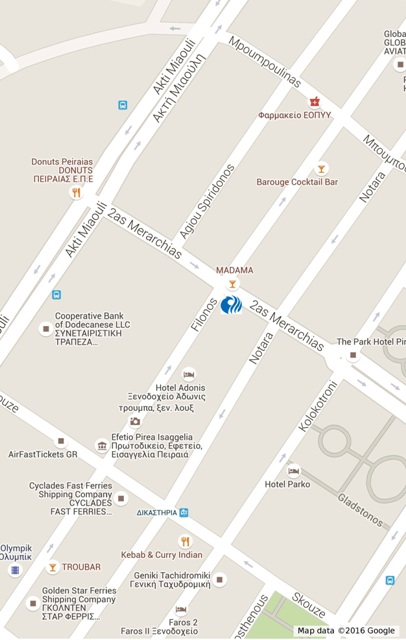

PHRS Announcement | New Address

May 19, 2016

We are pleased to announce that Phoenix Register of Shipping is relocating.

From Monday 23rd of May 2016 you will find us at our new address: 16, 2as Merarchias Str. - 4th Floor, 185 35, Pireas – Hellas.

Please note our email addresses and phone/fax numbers remain the same.

We will be glad to see you there with the first opportunity.